This is a question that we get a lot especially since we used to offer powder coated product and decided to drop that option and only ship bare metal material. We are obviously not professionals in this realm, but we definitely have had our fair share of rattle can and powder coated products and have seen the benefits and draw backs when it comes to armor applications.

1) What We've Seen With Powder Coated Armor

Powder Coating is a great tough coating with a lot of benefits. Typically it will take more of a hit to rub or scrape it off than a rattle can would. There is usually some sort of zinc infused primer laid before the parts are sprayed with whatever color they are going to be painted. This helps the metal not rust even if the top layer of coating is stripped off. The problem with powder coating is that it is expensive. A good powder coater can charge up to $300 in our area to coat a bumper. Which is only $100 less than the actual bumper itself. Now, if you can find someone to do it cheaper go for it. But in our experience the old saying stands, you get what you pay for. The second and last problem that we've seen with powder coating is that it is harder to touch up than spray paint. We typically compare it to an egg shell. Once it's cracked, it's cracked. You can touch it up with a rattle can to prevent rust but chances are you'll never be able to get it as thick and textured as it was when you paid $300 for it. Bottom Line is that powder coating is a superior coating and holds up well over many years, but many find it hard to pay a huge chunk of change when we're going to beat it against rocks anyways.

2) What We've Seen With Rattle Can Coated Armor

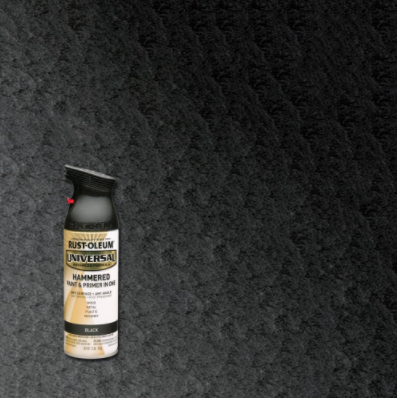

Believe it or not, the bumper in this picture was painted with a rattle can. Aside from the rusty exhaust, it looks just as good as any powder coated bumper out there. Where as a powder coat job would've costed hundreds of dollars, this paint job cost around $30 worth of paint, and a half days worth of labor from yours truly. It looks good, and the best part is that if it is damaged in any way, you can just touch it up with your can you had left over.

Now don't get us wrong, we definitely understand the draw backs of this method. First off, you have to know what your doing in some sort. If you've never spray painted something before, maybe test out keeping a steady hand on a piece of card board. Second, the type of paint you use is pretty critical. Rustoleum and Steel-It are two brands that we have been happy with in the past. Steel-It is one of the most expensive brands of "rattle can" paint, and for good reason. It's one of the few paints that wont contaminate a weld, and you pay the premium at $25 a can. Rustoleum's hammered finish is a good paint to use if you want a glossy textured finish. It sprays nice and even and holds up to abuse better than some of the cheaper alternatives. It is the paint shown in the picture above. We might be a little biased, but we believe that this is the easier and cheaper route. Just get some of the cheapest cans of paint you can find if you need some practice and then go for it.

Bottom Line we understand that rattle can jobs aren't for everyone, but with the right paint and if done correctly, it can turn out really nice.

If you have a brand new Jeep JL and you want to have a paint job with little to no flaws, and great protection. Go for the powder coat job. If you are building on more of a budget, you can get a great look from a rattle can job for much less money. It all depends on the person. But, this is what we have seen from our experience.